The Watchmaker’s Lathe

The watchmaker’s lathe is the most versatile tool at his command. With the lathe and its attachments, all manner of work can be done, from delicate, precision fitting of parts to making a complete watch, if need be. It enables the watchmaker to handle repairs he might ordinarily have to send out. And many jobs can be done in minutes with a lathe that would take hours to do by hand.

No simpler or more effective machine has yet been devised to do the multitude of jobs that the lathe can handle. Wheel cutting, jeweling, polishing, grinding pallet jewels, making balance staffs, opening wheels and jewel holes, uprighting, tapping screw holes, pivoting staffs – these are but a few of the tasks that can be done efficiently on a lathe.

Even though it is possible today to buy practically any part for any watch, many of these will need alteration to make a perfect fit. Alterations like changing the diameter of the roller seat, the collet seat, or the wheel seat on a balance staff can be done properly only on a lathe. As a result, the lathe is an investment that is well worth while. Even if used but a few minutes a day, it will repay its purchase price many times over. Properly used and maintained, the lathe will last a lifetime. It is considered a “must” tool for the professional.

THINGS TO LOOK FOR IN SELECTING A LATHE:

Choosing a lathe is largely a matter of personal choice and available budget, for today it is possible to find good lathes in almost every price range. However, price alone should not be the deciding factor, as accessories and minor features, such as finish, somewhat control the price.

There are more basic things to look for: The lathe bed should be of firm construction and preferably formed from a single casting. The head stock should be movable on the lathe bed, so the pulley can be aligned with the pulley on the motor.

The pulley should be a step pulley to permit adjustment of speed and power desired. It should also turn freely, bearings should be fitted, and no end shake or side shake should be apparent. It should be possible to adjust the bearings. The spindle should take standard size chucks and have a key way to assure each chuck fitting in the same position. Both lathe and chucks should run perfectly true. An index should be affixed to the pulley. An index is a circular plate with evenly spaced holes into which an index pin may be placed to lock the moving parts in any desired position. The lathe also should have a hinged or tip-over T-rest. The tailstock is less used than formerly when the individual watchmaker had to make most of his parts himself.

The beginner can postpone purchase of a tailstock. The professional usually acquires one in time. There are many accessories that can be had for use with the lathe. A few are described in the following pages, but these are by no means all that are available. Some are necessities. Others are simply an added convenience on certain jobs and can be considered special-purpose tools in nature. The type of work habitually done as well as available funds will largely determine the worth of an accessory to the individual watchmaker. The beginner is advised to start with just the basic items and add others only as a need is felt for them. Space here permits but a hint on the selection and usefulness of the lathe and its accessories. For detailed information on its possibilities, we refer you to Ward Goodrich’s authoritative book on the subject: “The Watchmaker’s Lathe.”

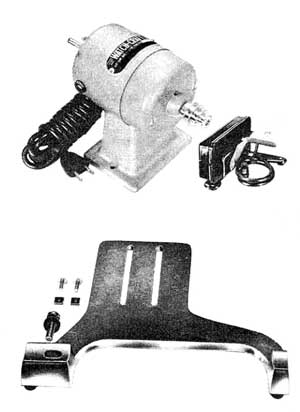

LATHE MOTOR

In years past the lathe was powered by a foot wheel. This may still be used in areas of the world where there is no electric power available. The modern method is to use a small, electric, reversible motor, about 1/10 horsepower, equipped with a foot rheostat to control the speed of the motor. It is best to select a motor designed for use with the lathe. The paint, enamel or chrome finish on the motor casing may somewhat control the price.

LATHE MOUNT

A portable lathe mount on which the lathe and motor are fastened is recommended for those who have no permanent working surface or who do not wish to mount the lathe and motor directly on the bench.

CHUCKS

Chucks are gauged in tenths of a millimeter. A number 20 chuck is twenty-tenths (20/10) of a millimeter. A No. 7 chuck is seven-tenths (7/10) mm., and so on. A beginner should have Nos. 16, 20, 32, and 40 chucks, plus a chuck for holding a cement brass. Other chucks may be added as the need arises. A chuck should be used only with metal stock of the same size, as spreading or compressing the jaws of a chuck will cause damage to the gripping surface and also cause the chuck to be off center.

SCREW CHUCK WITH CEMENT BRASSES

The cement brass is used on the lathe as a working surface for small parts that cannot be held in an ordinary wire chuck. The part, such as a jewel setting, is cemented and spun true on the cement brass.

CROWN CHUCKS

These chucks are used to hold crowns which have to be opened on the under side to fit over the pipe on the pendant of a case. They are designed primarily for crowns for pocket size watches. In lieu of this type chuck, as well as for smaller sizes, the crown may be cemented to a cement brass and the opening enlarged with a graver.

WHEEL CHUCK

This chuck is used to hold a train wheel in the lathe when polishing pivots, and so forth. The chuck will hold more than one size wheel. This chuck grips the ends of the teeth and so care should be taken to use the proper size chuck and not apply too much pressure or the teeth will be damaged. This chuck need be used only when too little of the pinion extends past the wheel to be gripped with a wire chuck. Another method of set-ting up this wheel would be to cement it to a cement brass.

CARBORUNDUM WHEELS

Small carborundum wheels can be mounted on an arbor chuck for grinding small steel work. When using these wheels on the lathe, take care to keep particles of carborundum from the bearings. Clean the lathe carefully after using carborundum.

ARBOR CHUCK

This chuck has a solid body and can be used to carry circular saws, wheel cutters, and the smaller size carborundum wheels.

BUFF CHUCK This solid body chuck has a tapered screw on which to mount polishing buffs. Buffing should be confined to small jobs and the same care should be taken of the lathe as when carborundum is used.

FILING FIXTURE

This fixture replaces the rest on your T-rest. It is used when filing across work held in the lathe, as when filing the square on a stem.

CARBORUNDUM WHEEL WITH ARBOR

This type wheel comes in several shapes and grades. It can be had in hard Arkansas stone and Aloxite for grinding watch crystals. However, as mentioned before, it is not advisable to use grinding wheels to excess in your lathe.

PIVOT POLISHER

This attachment is mounted on the lathe and is used to hold pivots while they are being straightened, burnished, ground, or polished. It is adjustable to fit all balance staffs. The pivot to be worked on extends all the way through the end bearing plate.

“L” TOOL REST

This tool rest is used with the face plate. Its design will allow close adjustment to the plate.

SLIDE REST This lathe attachment is of little use to the average watchmaker of today. It has various uses for the watchmaker who specializes in making watch parts. It is also used by model makers.

| « Truing calipers, balance screw cutters, overcoiling tweezers | Chuck holders, gravers, saw » |