Some hints on measuring as applied to watchmaking

The success of every undertaking depends largely on the ability to figure out and make practical plans, as well as to work correctly from plans already made. The ordinary method, used in the past, is not well adapted to our line of work in this scientific age; we should accustom ourselves to speak in exact terms as well as to work correctly to given measurements.

It is doubtless true that watchmaking is in greater need of exact and systematic measurements than any other trade, and it is also true, generally, that the average apprentice gets very little, if any, instruction in the art of measuring. It is a common idea that expensive gauges and elaborate instruments are required to produce first-class work; but often we may have the essential things right before us without thinking how to apply them. It is the object of this article to point out to the watchmaker, who wants to make things, how an ordinary micrometer may be used for practically all kinds of measuring.

Due to the small dimensions of our work, it is convenient to use a small unit for our linear measurements. The Metric system is very practical in this respect, using the millimeter, which is about 1/25 of an inch (exactly .03937″), as a unit, and subdividing the same into 1/10 and 1/100 mm. The fractions we usually write in decimal form, for example: 4.30 mm. instead of 4 3/10 mm., and 5.76 mm. instead of 5 76/100 mm., etc.

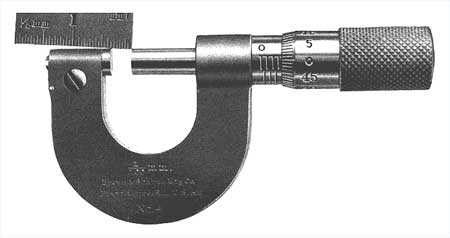

The screw in modern micrometers has a pitch of 1/2 mm., so one turn is divided into 50 parts, in order to measure 1/100 mm., and, consequently, we must turn the screw two complete turns for one millimeter, and the second turn should be read 55, 60, 65, etc., instead of 5, 10, 15. To avoid mistakes in the beginning, in reading the micrometer, it is advisable to use a straight scale, as shown in illustration, to verify the result.

The micrometer here shown indicates 3.51 millimeter. The square scale verifies the 3.5 millimeter; the micrometer shows the extra .01 millimeter.

The only other thing for the beginner to learn, in order to use the micrometer successfully for linear measurements, is to use as light a touch as possible in applying it to the objects which are to be measured. The unit for angular measurements is the degree, which equals 1/360 part of a circle. The degree is subdivided into sixty minutes, and the minute into sixty seconds. Instead of writing the words “degrees,” “minutes” and “seconds,” the symbols °, ‘, “, have been adopted; so, in order to denote one and one-half degrees, we write 1° 30’.

It may be well to point out an error very common among watchmakers to speak about linear measurements, such as the diameter of the pivots and thickness of mainsprings, etc., as so many “degrees.” This is entirely wrong, as such measurements should always be stated in fractions of a millimeter or inch.

| « Casing a movement | Pocket watch servicing. Hints and suggestions » |